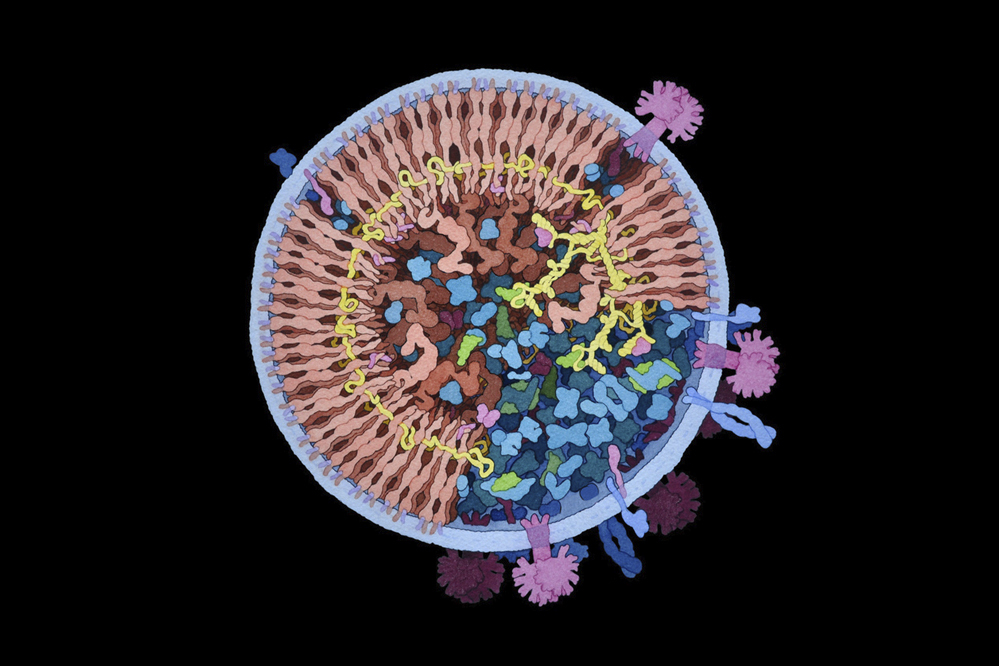

The expense of DNA sequencing has plummeted at a amount more quickly than Moore’s Law, opening huge marketplaces in the sequencing house. Genomics for cancer care by yourself is predicted to hit $23 billion by 2025, but sample preparation prices for sequencing have stagnated, leading to a major bottleneck in the space.

Regular sample planning, converting DNA from a saliva sample, for example, into something that can be fed to a sequencing machine, depends on a liquid-handling robot. It is basically a mechanical arm equipped with pipette tips that moves liquid samples to plastic plates and other devices positioned on the deck. These systems contain many fluidic transfers that lead to very poor utilization of reagents and samples, which suggests significantly less DNA sequenced. Additionally, they are methods of independent data silos that deficiency integration and depend on high priced consumables.

Compared with conventional liquid-dealing with automation, the suite of answers designed by MIT Media Lab spinoff Volta Labs delivers close-to-close integration for a broad variety of workflows. It’s a sleek different to high-priced liquid managing equipment and handbook pipetting. “Our technology is a modest-scale, benchtop device that is minimal-charge and has minimal consumable utilization, enabling speedy and versatile composition of new organic workflows,” states Volta Labs co-founder and Head of Engineering Will Langford SM ’14, PhD ’19.

The Volta platform is based on digital microfluidic technological innovation developed at MIT by Langford’s co-founder, Volta Labs CEO Udayan Umapathi SM ’17. The main basic principle behind the innovation is identified as electrowetting. It allows its users to manipulate droplets around a printed circuit board to complete organic reactions, automating from raw sample to geared up library that can be operate on a sequencing device.

Umapathi arrived at the Media Lab with what he describes as “a fascination for setting up automation from the ground up.” However experienced as an engineer, Umapathi has used his expertise to a wide range of fields. In 2015, he founded a startup that made world-wide-web and bodily resources to permit articles development for electronic production. Nevertheless, it was whilst functioning for a synthetic biology corporation, engineering liquid-managing programs for genome engineering remedies, that he recognized the scaling up of automation as a suffering position for the industry.

Meanwhile, Langford spent his MIT times at the Centre for Bits and Atoms, a proudly interdisciplinary plan that explores the boundary in between pc science and actual physical science. His study centered on the plan that engineering could discover from biology. Put yet another way, all of lifetime is assembled from 20 amino acids, so, believed Langford, why not attempt anything identical with engineering?

In observe, this intended he constructed integrated robots from a small established of millimeter-scale components. “Ultimately, I was seeking to make engineering more like biology,” he reflects. “I see Volta as an opportunity to flip that on its head and use automation to treat biology far more like engineering. We want to give biologists tools to manipulate liquids and organic reactions at a finer granularity and with much more digital overall flexibility.”

While Volta’s automation platform simplifies sample prep by integrating difficult workflows, it also drives down expenditures in the house with a new consumable building. Involving the circuit board and the sample board is a consumable layer, which is taken off and changed following just about every operate. Conventional consumables are pricey, conductively coded plastics or large microfluidic structures. Volta, on the other hand, makes use of a basic plastic film to lessen the expense of consumables, which opens the doorway for the common adoption of gene sequencing.

All of this points to a a lot more economical and inclusionary product in the gene sequencing room. Many thanks to Volta, before long, it would not be just large biotechnology organizations with the capability to devote in automation. Educational labs, main amenities, and modest-to-medium biotech corporations won’t require to stress about no matter whether they can pay for an high priced mechanical robot. “The point that excites me is that we’re furnishing early-phase and mid-to-low-throughput biotech organizations with highly effective instruments that will make it possible for them to compete with larger gamers, which is very good for the market as a complete,” claims Umapathi.

And the simple fact is that classic automation equipment used in the biotechnology room come with their very own established of issues. They are error-inclined and you cannot scale them. Contemplate Illumina’s NovaSeq sequencer. It is capable of sequencing 48 full human genomes in underneath two times — which is 20 billion one of a kind reads — but there is presently no automation to feed individuals devices at scale. “To run these devices day in and day out, the charge basically does not make perception, which is why we have to deal with the price of sequencing and sample prep,” claims Umapathi.

Volta’s procedure is constructed on solid-condition electronics, and the Boston-primarily based startup is hunting to leverage the scalability of the semiconductor fabrication business and the PCB producing marketplace. “The target,” explains Langford, “is to permit biologists to create an experiment and modify it quickly, iterate on it, and generate the facts needed to see biology at scale.”

Past the sample prep bottleneck, eventually, the do the job of Umapathi and Langfordwork will influence a wide variety of purposes in the synthetic biology business and the biopharma field. Diagnostics will be reworked, in accordance to Umapathi. “We can enable the biology sector by cutting down on the use of pipette suggestions by 20 or 50 moments. In unique workflows, we can virtually totally eliminate this bottleneck in the offer chain,” he states.

To execute all of this, to genuinely innovate in a field as sophisticated as biology, Umapathi and Langford insist that a multidisciplinary units viewpoint is essential. It is what informs the Volta approach to genomic sequencing in certain, and biology as a whole. “Volta is a new sort of biotechnology organization,” says Umapathi. “It’s inescapable that a lot more engineers and methods thinkers and individuals who want to establish instruments to engineer biology far better will be a part of organizations like ours or get started their possess.”

Turning biology into an engineering basic principle is no modest feat, but in accordance to Umapathi and Langford, it is a requirement.